| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Discussion

and References

|

| |

|

Information about

Reinforcement of Welded Branch Connections:

|

| |

|

ASME B31.3 Process

Piping, para. 304.3.3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Tables and Standards

|

| |

-

|

Table A-1 Basic Allowable Stresses in

Tension for Metals

|

| |

-

|

Table A-1M

Basic Allowable Stresses in Tension for Metals (Metric)

|

| |

-

|

Table A-1B Basic Quality Factors for

Longitudinal Weld Joints in Pipes and Tubes, Ej

|

| |

-

|

Table 304.1.1 Values of Coefficient Y for t

< D/6

|

| |

-

|

Table 302.3.5 Weld Joint Strength Reduction

Factor, W

|

| |

-

|

ASME B36.10M-Welded and Seamless Wrought

Steel Pipe

|

| |

-

|

ASME B36.19M-Stainless Steel Pipe

|

| |

-

|

Mill Tolerance = 12.5%

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Equations

for Wall thickness calculation of straight pipes under internal pressure

(304.1):

|

| |

|

|

| |

|

For t < D/6, the thickness should be calculated by the

equation:

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Select T̅ from

ASME B36.10M or B36.19M

|

| |

|

Mill

Tolerance = 12.5%. (See ASTM Standards & appendix S of ASME B31.3)

|

| |

|

T = T̅ (1.00-0.125) = T̅ (0.875) Minimum

thickness required, considering a mill tolerance of 12.5%

|

| |

|

Thickness for design pressure

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

t =

|

PD

|

|

|

|

|

|

(eq. 3a as per par. 304.1.2)

|

|

|

|

| |

|

2(SEW + PY)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

The

parameters in the wall thickness calculation of straight pipes under internal

pressure

|

| |

|

equations

above are:

|

|

|

|

|

|

|

|

|

|

| |

|

T̅ = Nominal pipe wall

thickness, inches (mm) from ASME

B36.10M or B36.19M

|

|

|

| |

|

T = Minimum thickness considering a mill tolerance of 12.5%,

inches (mm)

|

| |

|

tm = Minimum thickness required,

inches (mm)

|

| |

|

t = Thickness for design pressure,

inches (mm)

|

| |

|

c = Sum of allowance for corrosion, erosion, slots and threads,

inches (mm)

|

| |

|

P = Internal design pressure, psig (barg) (1bar = 100 kN/m2)

|

|

|

D = External diameter, inches (mm)

|

| |

|

E = Quality factor (table A-1B) of ASME B31.3

|

| |

|

S = Allowable stress at the design temperature, psi (Mpa)

(table A-1 or A-1M) of ASME B.31.3.

|

| |

|

Y = Coefficient that depends on the material and design

temperature (table 304.1.1) of ASME B31.3.

|

| |

|

W = Stress reduction factor of welded joint, paragraph

302.3.5(e) and table 302.3.5 of ASME B31.3

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

The formulas below is used in the pressure design of branch

connections. It is illustrated in Fig. 304.3.3, which does

|

| |

|

not indicate details for construction or welding. Some of the

terms defined in Appendix J are subject to further

|

| |

|

definitions or variations, as follows:

|

|

|

|

| |

|

b = subscript referring to branch & h = subscript referring to run or

header

|

| |

|

d1 = effective length

removed from pipe at branch.

|

| |

|

For branch intersections where the branch opening is a

projection of the branch pipe inside diameter (e.g., pipe-to-pipe fabricated

branch),

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

d₁ =[Db ̶

2(Tb

̶ c)]/sin β

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

d2 = “half width” of reinforcement zone

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

d₂ = d₁ or (Tb ̶

c) + (Th

̶ c)+

|

d₁

|

|

|

|

|

|

| |

|

2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

L4 = height of

reinforcement zone outside of run pipe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

L₄ = 2.5(Th ̶ c) or 2.5(Tb

̶ c)+Tr

|

|

, whichever is less

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Tb = branch pipe thickness (measured or minimum in accordance

with the purchase specification) except for branch connection fittings (see

para. 300.2). For such connections the value of Tb for use in calculating L4, d2,

and A3 is the

thickness of the reinforcing barrel (minimum per purchase specification),

provided that the barrel thickness is uniform (see Fig. K328.5.4) and extends

at least to the L4

limit (see Fig. 304.3.3.)

|

| |

|

Tr = minimum thickness of reinforcing ring or saddle made from

pipe (use nominal thickness if made from plate)

|

| |

|

= 0, if there is no

reinforcing ring or saddle

|

| |

|

t = pressure design thickness of

pipe, accordingto the appropriate wall thickness equation or procedure in

para. 304.1. For welded pipe, when the branch does not intersect the

longitudinal weld of the run, the basic allowable stress, S, for the pipe may

be used in determining th for the purpose of reinforcement calculation only. When the

branch does intersect the longitudinal weld of the run, the product SEW (of

the stress value, S; the appropriate weld joint quality factor, Ej, from

Table A-1B; and theweld joint strength reduction factor, W; see para.

302.3.5) for the run pipe shall be used in the calculation. The product SEW

of the branch shall be used in calculating tb.

|

| |

|

β = smaller angle between axes of branch and run.

|

| |

|

Required Reinforcement Area. The reinforcement area, A1, required for a branch connection under internal pressure is:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₁ =th d₁ (2 ̶ sin β)

|

|

|

|

|

(6)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

For a branch connection under external pressure, area A1 is

one-half the area calculated by eq. (6), using as th the thickness required

for external pressure.

|

| |

|

Available Area. The area available for reinforcement is defined

as

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₂ +A₃ + A₄ ≥ A₁

|

|

|

|

|

|

(6a)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

These areas are all within the reinforcement zone and are

further defined below.

|

| |

|

I.Area A2 is the area resulting from excess thickness in the run pipe

wall

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₂ = (2d₂ ̶ d₁)(Th ̶ th ̶ c)

|

|

|

|

(7)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

II.Area A3 is the area resulting

from excess thickness in the branch pipe wall

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₃ = 2L₄(Tb ̶ tb

̶ c)]/sin β

|

|

|

|

(8)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

If the allowable stress for the branch pipe wall is less than

that for the run pipe, its calculated area must be reduced in the ratio of

allowable stress values of the branch to the run in determining its

contributions to area A3.

|

| |

|

III.Area A4 is the area of other

metal provided by welds and properly attached reinforcement. [See para.

304.3.3(f).] Weld areas shall be based on the minimum dimensions specified in

para. 328.5.4, except that larger dimensions may be used if the welder has

been specifically instructed to make the welds to those dimensions.

|

| |

|

In ring

|

|

|

|

|

|

|

|

| |

|

A₄ = (Tr)(Dr -

|

Db

|

)

|

|

|

|

|

|

|

|

| |

|

sin β

|

|

|

|

|

|

|

|

| |

|

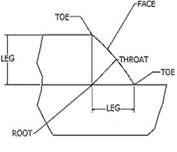

In fillet welds

|

|

|

|

|

|

|

|

| |

|

Considering all

fillet welds are equivalent to 45 deg fillet welds

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₄ = No. Fillet welds x Aby fillet weld

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

A₄ =

4 x 1/2 x Leg²

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Reinforcement Zone. The reinforcement zone is a parallelogram whose length

extends a distance, d2, on each side of the centerline of the branch pipe and whose

width starts at the inside surface of the run pipe (in its corroded

condition) and extends beyond the outside surface of the run pipe a

perpendicular distance, L4.

|

| |

|

Multiple Branches.

When two or more branch connections are so closely spaced that their

reinforcement zones overlap, the distance between centers of the openings

should be at least 1-1⁄2 times their average diameter, and the area of

reinforcement between any two openings shall be not less than 50% of the

total that both require.

|

| |

|

Each opening shall have adequate reinforcement in accordance

with paras. 304.3.3(b) and (c). No part of the metal cross section may apply

to more than one opening or be evaluated more than once in any combined area.

(Consult PFI Standard ES-7, Minimum Length and Spacing for Branch

Connections, for detailed recommendations on spacing of welded nozzles.)

|

| |

|

Added Reinforcement

|

| |

|

I.Reinforcement added in the form of a ring or saddle as part of

area A4 shall be

of reasonably constant width.

|

| |

|

II.Material used for reinforcement may differ from that of the

run pipe provided it is compatible with run and branch pipes with respect to

weldability, heat treatment requirements, galvanic corrosion, thermal

expansion, etc.

|

| |

|

III.If the allowable stress for the reinforcement material is

less than that for the run pipe, its calculated area must be reduced in the

ratio of allowable stress values in determining its contribution to area A4.

|

| |

|

IV.No additional credit may be taken for a material having

higher allowable stress value than the run pipe.

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|